VSB - Technical University of Ostrava, is proud to be one of the few European universities to have a dedicated Restoration Workshop. This workshop operates under the auspices of the Faculty of Mechanical Engineering and focusses on the restoration of historic motorcycles. Experts from the fields of structural and process engineering, applied mechanics, mechanical engineering and transport technology combine antiquated methods and materials with cutting-edge technologies and resources, such as the 3D printing of metals, composites and plastics, 3D scanning, and CAD/CAM/CAE technologies. The restoration workshop was established with the financial support of the Moravian-Silesian Region and a private collector who donated his collection for further renovation as part of the teaching process and, subsequently, its public display. Students final theses are created as part of a specialisation in the process of preserving, repairing, and maintaining the historic vehicles.

Engineers at the Restoration Workshop are engaged in reverse engineering, "which means that a part or a set of parts that are now difficult to find, need to be redesigned and subsequently manufactured" explains Lukáš Kudrna, who is a mentor at the Restoration Workshop and an employee of the Faculty of Mechanical Engineering at VSB-TUO, "in exceptional cases the part has not been preserved at all, and in this situation, period images need to be studied to enable the team to manufacture the replacement part".

Reverse engineering uses the technologies of 3D scanning, 3D printing, graphics software, etc. “It always depends on the specific case. If it is a component with a simple shape, you will measure it and model it,” explains Lukáš Kudrna about the process. A 3D scanner is used to capture the more complex parts, as this can do this with an accuracy of 0.03mm. The subsequent 3D model must then be modified or remodelled. "You then print the finished model on a 3D printer or manufacture it on a CNC machine. Before the actual printing, the production technology must be chosen, which will affect the final model" he adds. Within the University, the Restoration Workshop cooperates with the PROTOLAB 3D printing centre, which is equipped with modern machinery and ranks not only among the best in the Czech Republic, but also abroad. "We mainly cooperate on the creation of 3D models and the production of final prints, which are often made of 316L stainless steel or polyamide" he says. "In the future, it will also be possible to print from titanium or aluminium." The cooperation of the Restoration Workshop with the PROTOLAB centre is also linked to science, research, and development. "Through practice, we gain experience, which we pass on to our students." There is great interest among students in working in the workshop.

The focus of Lukáš Kudrna’s dissertation will take advantage of the technologies available at VSB - Technical University of Ostrava and compare the use of 3D modelling and traditional metal casting techniques. "During casting, the part is significantly modified. Reverse engineering straddles multiple disciplines, it is very complex" he explains. According to him, the Restoration Workshop cannot do without casting technology.

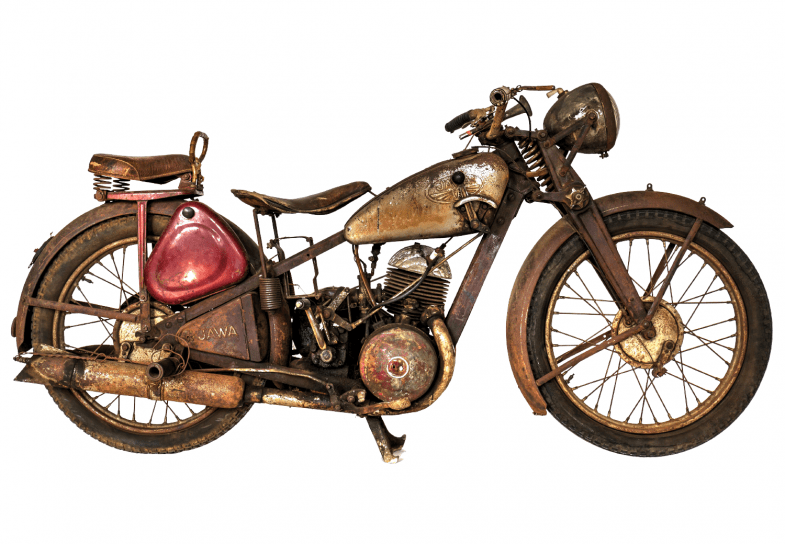

In the Restoration Workshop, in cooperation with a professional restorer, they are currently restoring a Jawa 350 SV motorcycle from 1934. Underneath amateurish coatings of paint the original surface treatment has been uncovered and restored. The work of the Restoration Workshop has recently been presented by Lukáš Kudrna at the Retromobile Show in Paris.

All work undertaken on historic technology at VSB-TUO is carried out in accordance with the requirements of the Turin Charter, which is a set of basic instructions and procedures for the use, maintenance, preservation, renovation, and repair of historic vehicles.