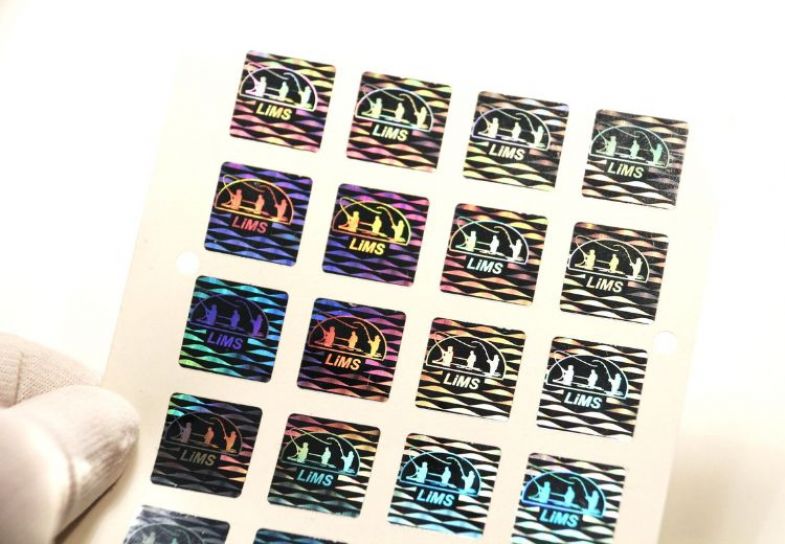

Counterfeiting of various documents, banknotes, or tickets is a common problem that can be encountered in everyday life, even when shopping. Recognising the scale and seriousness of the problem, researchers at Kaunas University of Technology (KTU), Lithuania, decided to look for ways to further reduce the risk of counterfeiting by inventing a new method to produce holographic security labels.

Holograms have been used as an anti-counterfeiting tool for some time. Now they can be seen on pharmaceutical packaging, brand labels, and even toys. Holograms are much more difficult for forgers to counterfeit than, for example, the watermarks on banknotes, as they require complex micro and nano technologies that traditional printing houses lack.

Combining two technologies has led to international recognition

To enhance the level of holographic protection against forgery and to address this worldwide problem, Lithuanian researchers from KTU Institute of Materials Science came up with the idea of combining two technologically different methods.

One of them is a dot-matrix hologram made of small dots that refract light. “Each dot, which is barely smaller than a human hair, records a periodic structure made up of lines known as a diffraction grating.

It causes the light to play in a way that is visible to the observer’s eye, similar to a CD or DVD,” explains one of the inventors Dr Tomas Tamulevičius.

Dr Viktoras Grigaliūnas, a KTU researcher who also contributed to the development of the technology, adds that this dot-matrix hologram, although relatively faster and cheaper and used to expose large areas of the hologram, does not guarantee a very high level of protection.

This is why electron beam lithography is used to expose smaller areas of the hologram.

“It is a more advanced technology that allows to form high-resolution structures and is practically inaccessible to potential hologram counterfeiters,” says Grigaliūnas, a researcher at the KTU Institute of Materials Science and head of the Research Laboratory of Nano and Microlithography Laboratory.

The combination of these two techniques has received international recognition – the invention has been recognised by the US Patent and Trademark Office and the Japanese Patent Office. This protects the intellectual property created by the scientists and allows them to license it to interested companies.

In addition, holographic label technologies developed by KTU researchers are already widely used for metrological verification, on car license plates, on the packaging of various products, and on event tickets and diplomas.

Warns staying alert

“Admittedly, holograms were invented for a completely different purpose, to increase the resolution of electronic microscopy,” says Prof. Tamulevičius.

According to the scientist, the breakthrough of holograms in the fight against counterfeiting came when it was realised that once the original hologram was recorded, it could be copied mechanically by pressing it into another material. This has led to a substantial expansion in the production quantities of holograms.

Fictional films and their holograms of people and even entire cities have led to a rather diverse perception and interpretation of the term itself. The rapid advances in technology have allowed some fictional ideas to become reality, and today even holograms in full concert arenas can be seen.

“However, our research is closer to classical holograms,” adds Tamulevičius. The scientist mentions that hologram technology has been developed at KTU Institute of Materials Science for more than 20 years. During this time, the researchers have not only refined their activities, received a patent for their invention, but also set up a start-up “Holtida” which offers companies the opportunity to purchase solutions developed by scientists in their laboratories.

When strengthening the protective measures themselves, Tamulevičius encourages consumers to keep in mind that holograms can also be counterfeited, so he encourages everyone to inspect the holographic security labels and to remain alert.

“Hologram manufacturers usually try to make holograms as bright as possible; the visible features, such as clear objects and different colours, do not glow by chance. Only specific elements of the brand are integrated into the image with different sizes of characters visible. If an observer sees a random glow, it is likely to be either a very unsophisticated hologram or a fake,” he says.

In collaboration with colleagues from the Faculty of Informatics (IF) at KTU, the inventors have developed another innovation. It is a digital application for smart devices called “HoloApp”, which allows you to see what the hologram looks like on the screen. This enables a better understanding and experience of what a hologram should look like and the ability to identify if it is forged.

The commercialisation of the product is facilitated by KTU National Innovation and Entrepreneurship Centre – a one-stop shop for knowledge-intensive businesses to contact research.

Find out more about materials science research at Kaunas University of Technology, Lithuania.